Highlogo Initial set-up

THANKS! You have a Highlogo... LC/LCX/LCSX with integrated dynamic pressure level switch.

Follow the steps below to complete the setup.

Step 1:

Here we go..

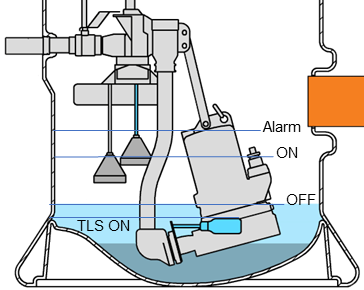

Switching heights using the example: Installation in the PKS 800 sewage sump

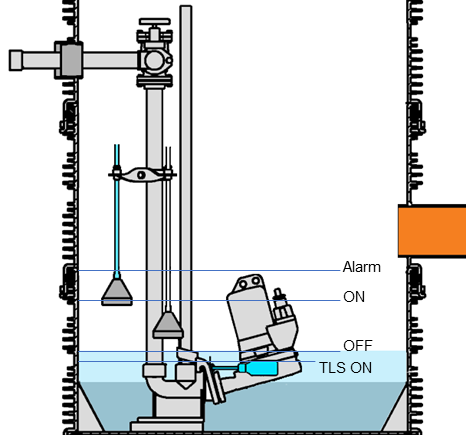

Use the manual to check whether the installation position of the two pitot tubes and the blue immersion switch (TLS = dry-running protection) in the sump are correct.

Only then can the system work properly.

Switching heights using the example: Installation in the sewage sump with foot coupling

Step 2

The initial set-up

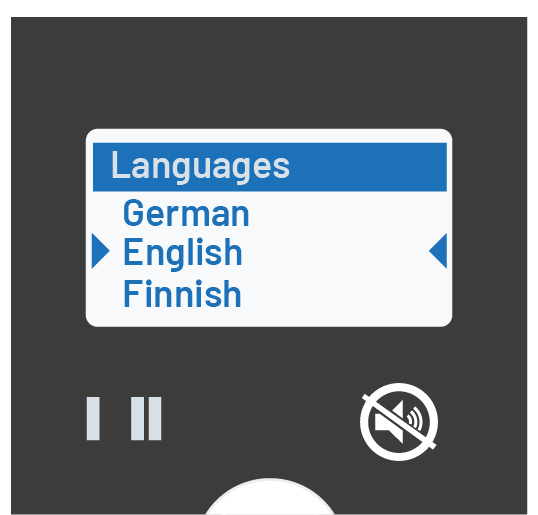

Turn and press the multifunction knob to move through the initial set-up menu of the control unit.

First select the language and then the display contrast.

Step 3

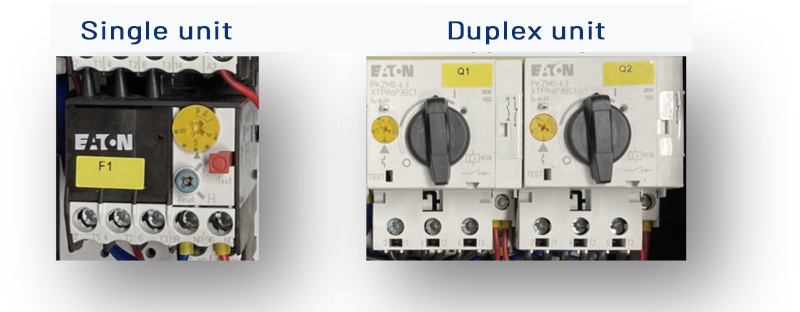

Now specify whether it is a single or duplex pump unit.

Note: HighLogo 2 control unit for duplex pump systems can also be operated with only one pump if you select "Simplex".

Step 4

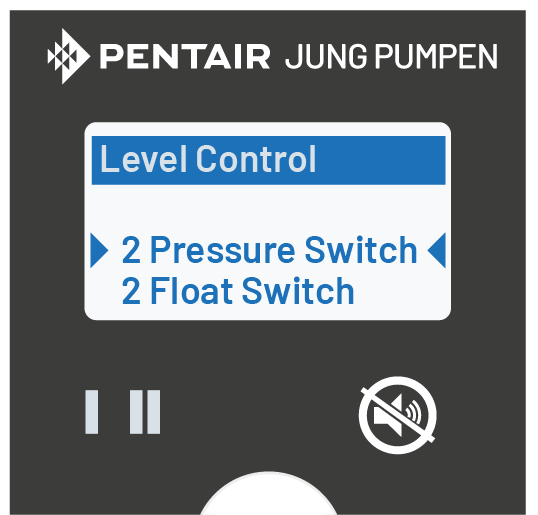

Now the installed level control is activated and adjusted.

Select here 2 pressure switches and confirm. The pressure switches are already built into the unit.

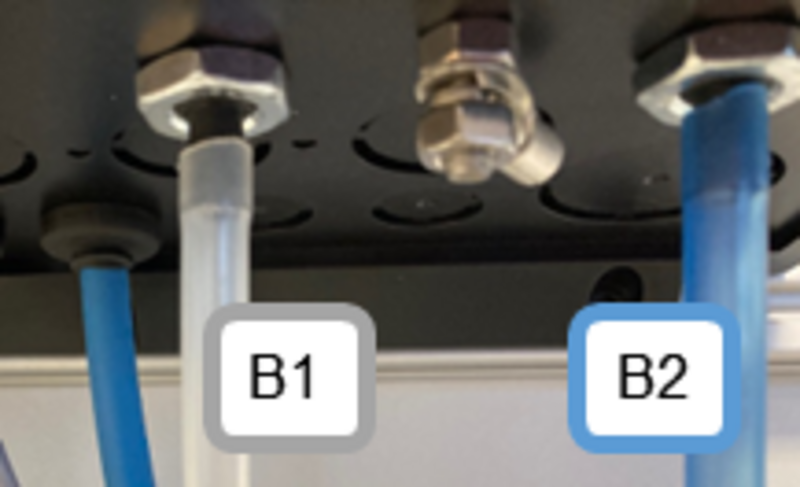

The two air hoses white (basic load at B1) and blue (alarm at B2) must be firmly attached to the hose nozzles.

Step 5

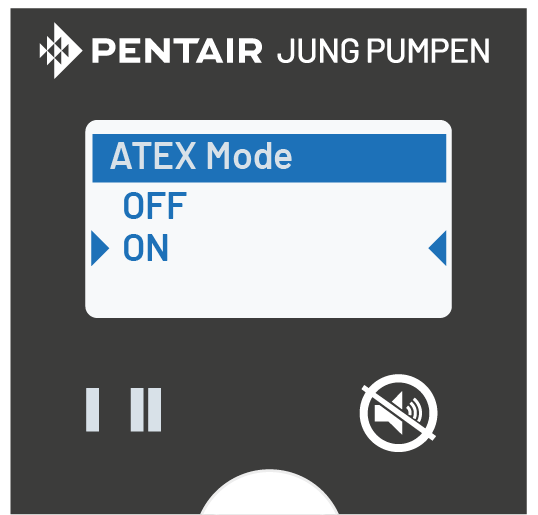

ATEX Mode ON/OFF

By activating the ATEX mode, the connected pump(s) are monitored according to the currently valid safety regulations.

This includes:

Dry-running protection

Run-time monitoring (S2 time)

Non-automatic reset after overtemperature triggering

If the ATEX mode is not activated, all these three protective functions are switched off!

Step 6

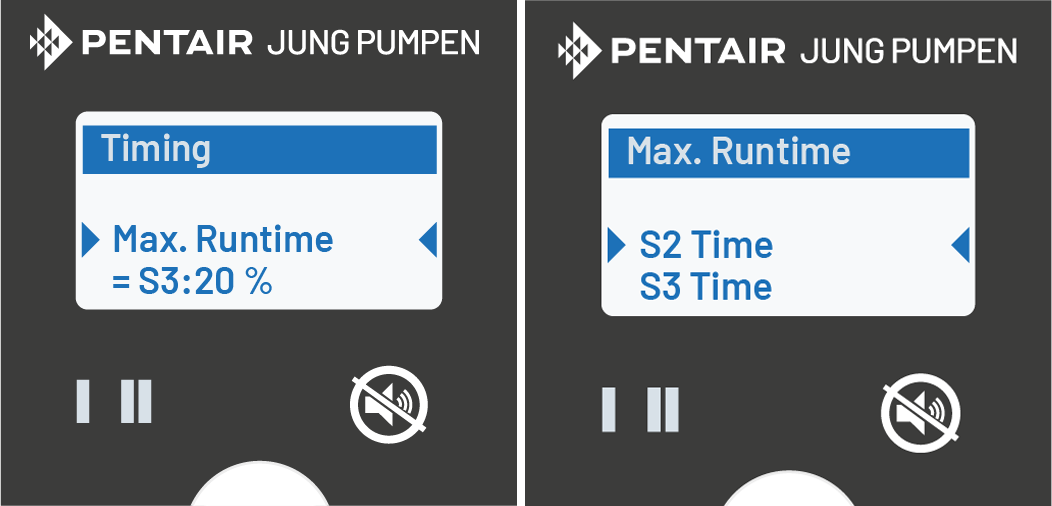

Setting the runtime monitoring

Note: Only to be set when ATEX mode is activated.

Otherwise continue with step 8.

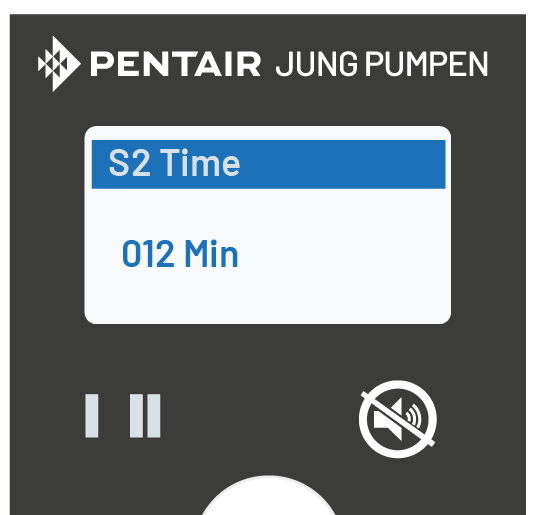

Select S2 Time and set the running time to the value from the pump's technical data (operating instructions).

Often used MultiCut pumps:

20/2 M Plus: 12 Min.

35/2 M: 27 Min.

36/2 M: 20 Min.

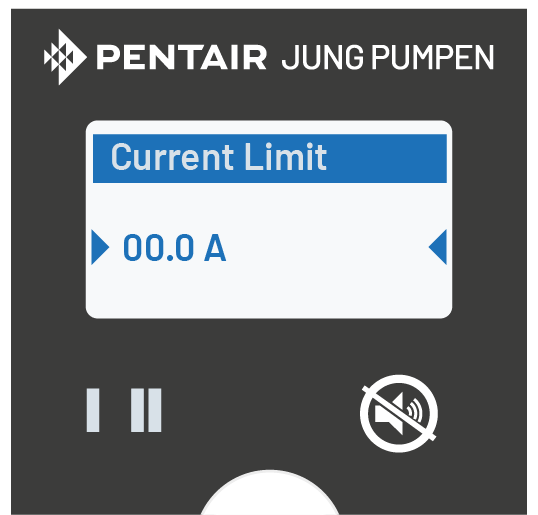

Step 7

Set or deactivate current monitoring by selecting 0.00 A

Note:

This function is only required if there is no mechanical motor protection in the control unit. It monitors the current consumption electronically on one phase. If it is activated, the pump switches off when the set limit is reached. The tripping characteristic of a slow-blow fuse is simulated.

This function should be deactivated on controls with explosion protection or activated ATEX mode.

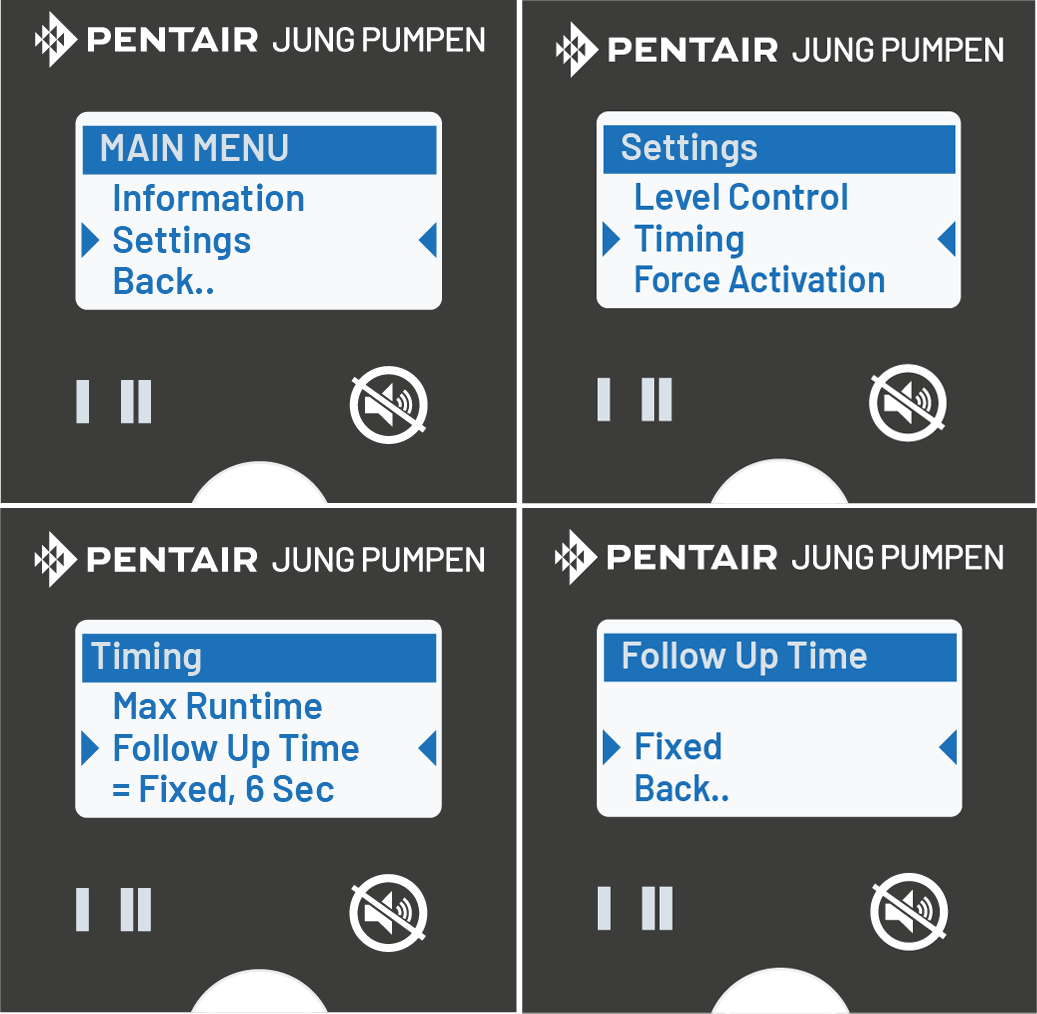

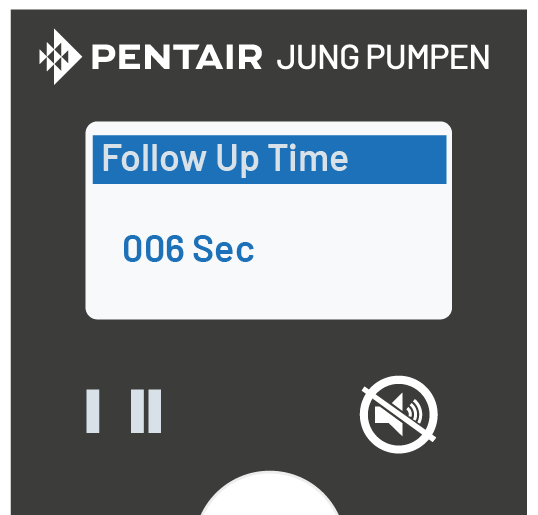

Step 8

Set the pump run-on time

To enter the settings menu, turn the multifunction knob to the right and select "Settings" by pressing it.

Then navigate further as shown above.

The factory setting is 6 sec. This depends on the operating point of the pump.

In automatic mode, the run-on time starts when the base-load pressure switch (B1) switches off while the pump is running. The lower back-pressure bell is about half submerged.

The run-on time is set correctly when the pitot tube has risen approx. 5 cm out of the water after the pump has been switched off.

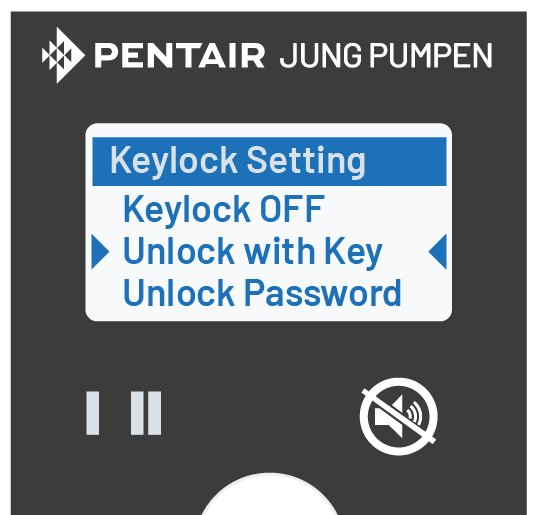

Step 9

Recommendation: Secure the control unit against unauthorised access

By default, the HighLogo control unit is not secured against inputs after commissioning.

If you want to protect the unit against unauthorised access, you can activate the key lock or set a 4-digit password. The standard password can be found in the HighLogo control unit's manual.

Step 10

Finally, check the motor protection for correct setting

This step is normally carried out during the electrical installation of the control unit or after connecting the pump(s).

The door must be opened for this. Please observe the safety instructions!

Disconnecting the power supply may only be carried out by a qualified electrician!

Check whether the motor protection is correctly set to the rated current consumption of the pump.

You can find the value in the pump's technical data sheet.

You can make the setting by turning the yellow knob.

Ready!

Initial set-up completed

Your control unit is now configured for operation with the correct basic settings.

Finally, check that the operating setting of the pump(s) is set to automatic.

After filling the pump shaft to the switch-on level, pumping down is started.

Now take some more time for advanced settings such as:

- Alarm behaviour

- Maintenance frequency

- Service telephone number

Everything else you can find in the manual of the control unit.

Video tips:

- We have also created a YouTube video on how to commission the HighLogo control unit.

- If you have any questions about the principle of level detection or dry-running protection, we recommend this YouTube video.

Have a look!

For your safety - also think about the maintenance of your pumping station!

A pumping station must be maintained regularly in accordance with DIN EN 12056.